How to extend the service life of bucket tooth

1.After years of feedback from the excavator market, it has been proved that during the use of excavator bucket teeth, the internal bucket teeth of the outer bucket arms at both ends wear out 30% faster, so we recommend that the bucket teeth be used for a period of time. Position, thereby extending the service life of all bucket teeth.

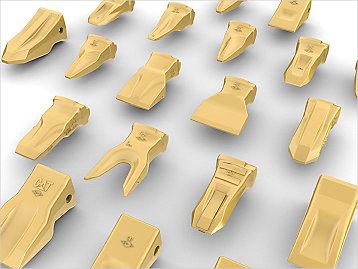

2.The use of bucket teeth should also pay attention to the working environment. Different working environments use different bucket teeth. The targeted use of bucket teeth can reduce the wear of the bucket teeth and at the same time reduce the excavation resistance and save the fuel consumption of the excavator.

3.The correct operation of the excavator driver during driving is also very important to the protection of the bucket teeth. Correct operation can reduce the direct collision between the bucket teeth and the object, and reduce the rupture of the bucket teeth and the cracking of the large and small arms caused by irregular operation. occur.

4.The wear of the gear seat also plays a key role in the service life of the bucket teeth of the excavator. It is recommended to replace each gear seat after 10%-15% wear. Because the gap between the worn tooth seat and the bucket tooth is too large, it will change the stress point and fit between the two, which will cause the bucket tooth to break.

5.Because most of the bucket teeth do not consider the left and right forces in the design, it is necessary to avoid swinging the excavating arm left and right when the bucket teeth are subject to greater resistance, which can reduce the excessive force between the bucket teeth and the tooth seat And the probability of breakage.

2.The use of bucket teeth should also pay attention to the working environment. Different working environments use different bucket teeth. The targeted use of bucket teeth can reduce the wear of the bucket teeth and at the same time reduce the excavation resistance and save the fuel consumption of the excavator.

3.The correct operation of the excavator driver during driving is also very important to the protection of the bucket teeth. Correct operation can reduce the direct collision between the bucket teeth and the object, and reduce the rupture of the bucket teeth and the cracking of the large and small arms caused by irregular operation. occur.

4.The wear of the gear seat also plays a key role in the service life of the bucket teeth of the excavator. It is recommended to replace each gear seat after 10%-15% wear. Because the gap between the worn tooth seat and the bucket tooth is too large, it will change the stress point and fit between the two, which will cause the bucket tooth to break.

5.Because most of the bucket teeth do not consider the left and right forces in the design, it is necessary to avoid swinging the excavating arm left and right when the bucket teeth are subject to greater resistance, which can reduce the excessive force between the bucket teeth and the tooth seat And the probability of breakage.